Full Length Ultrasonic Inspection

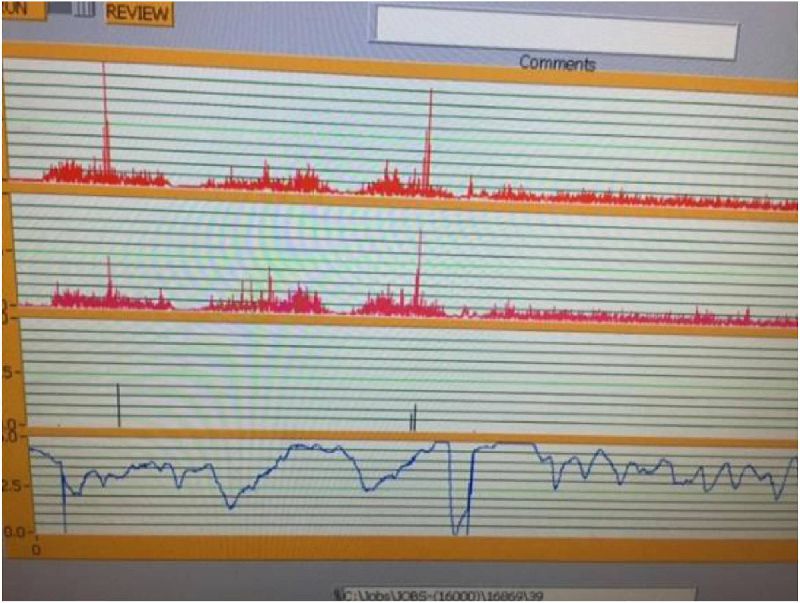

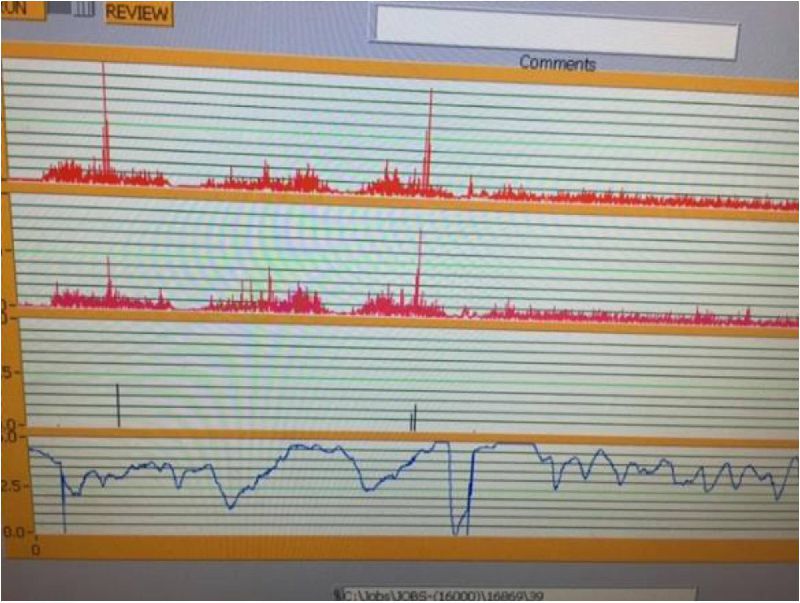

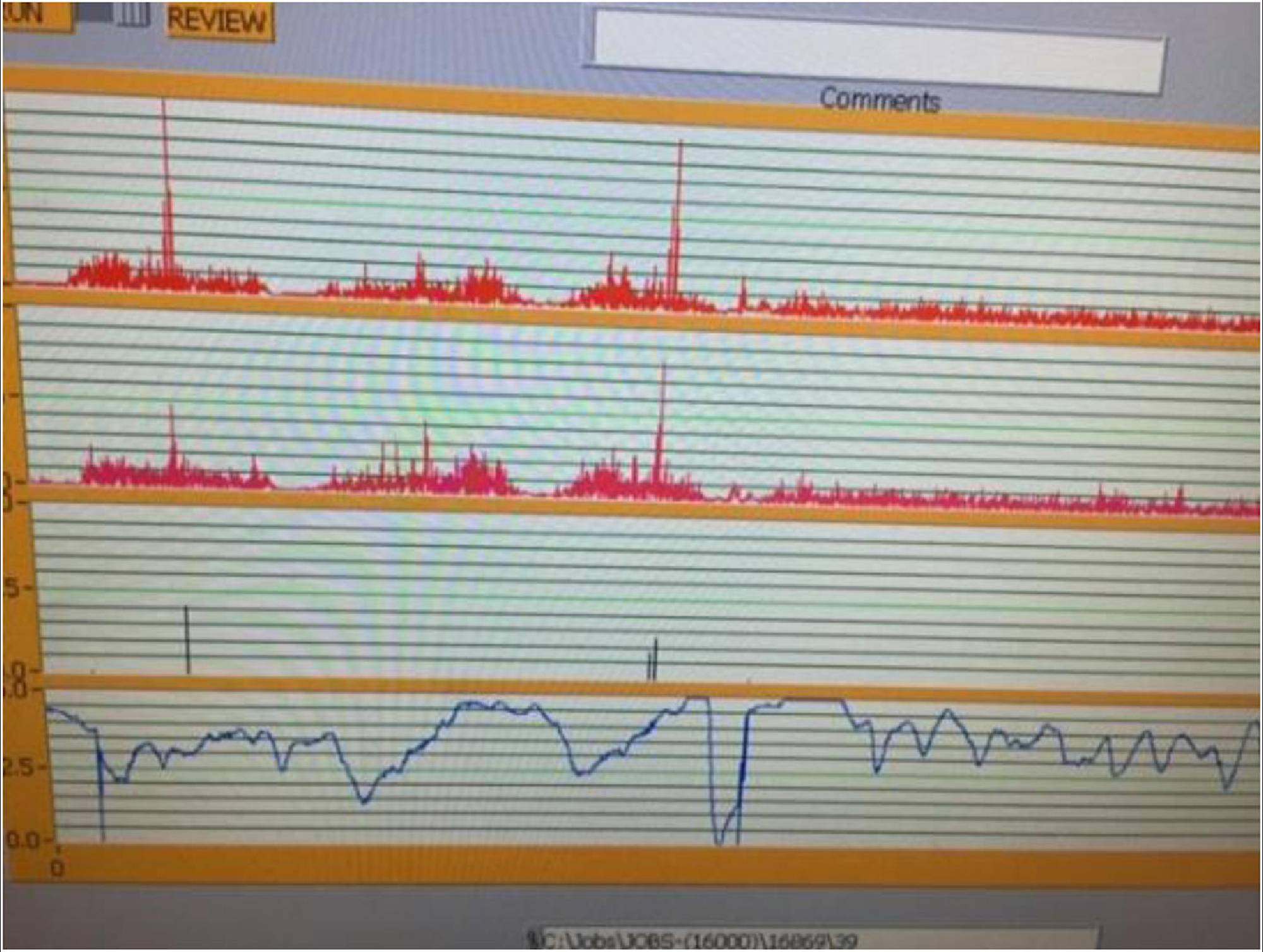

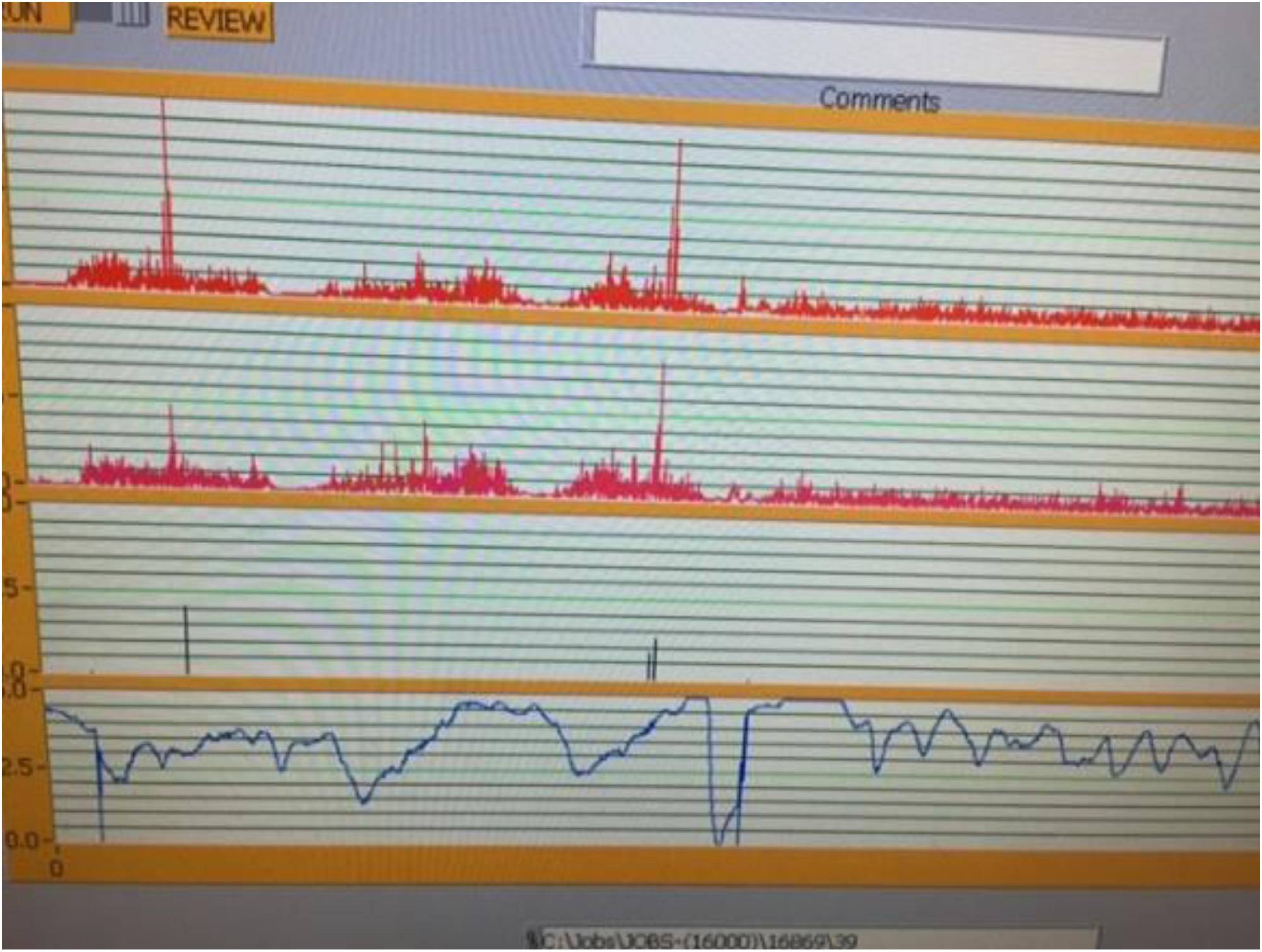

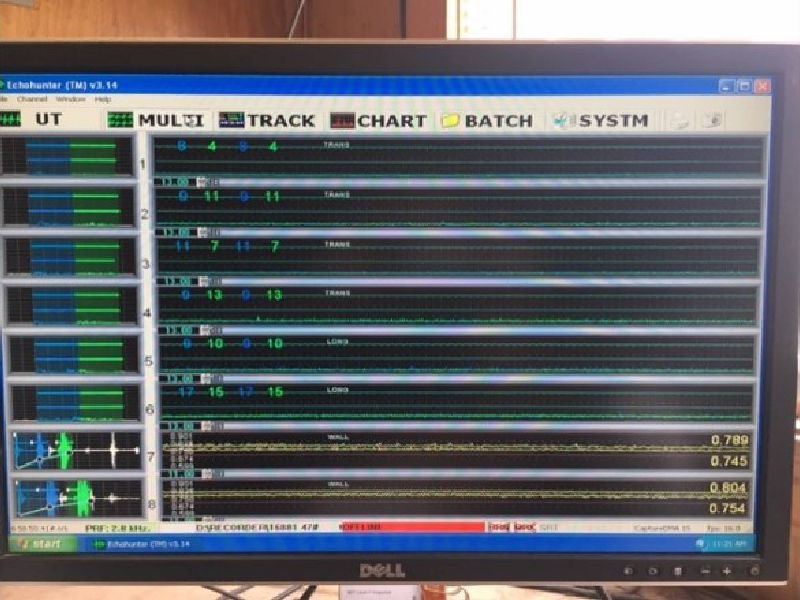

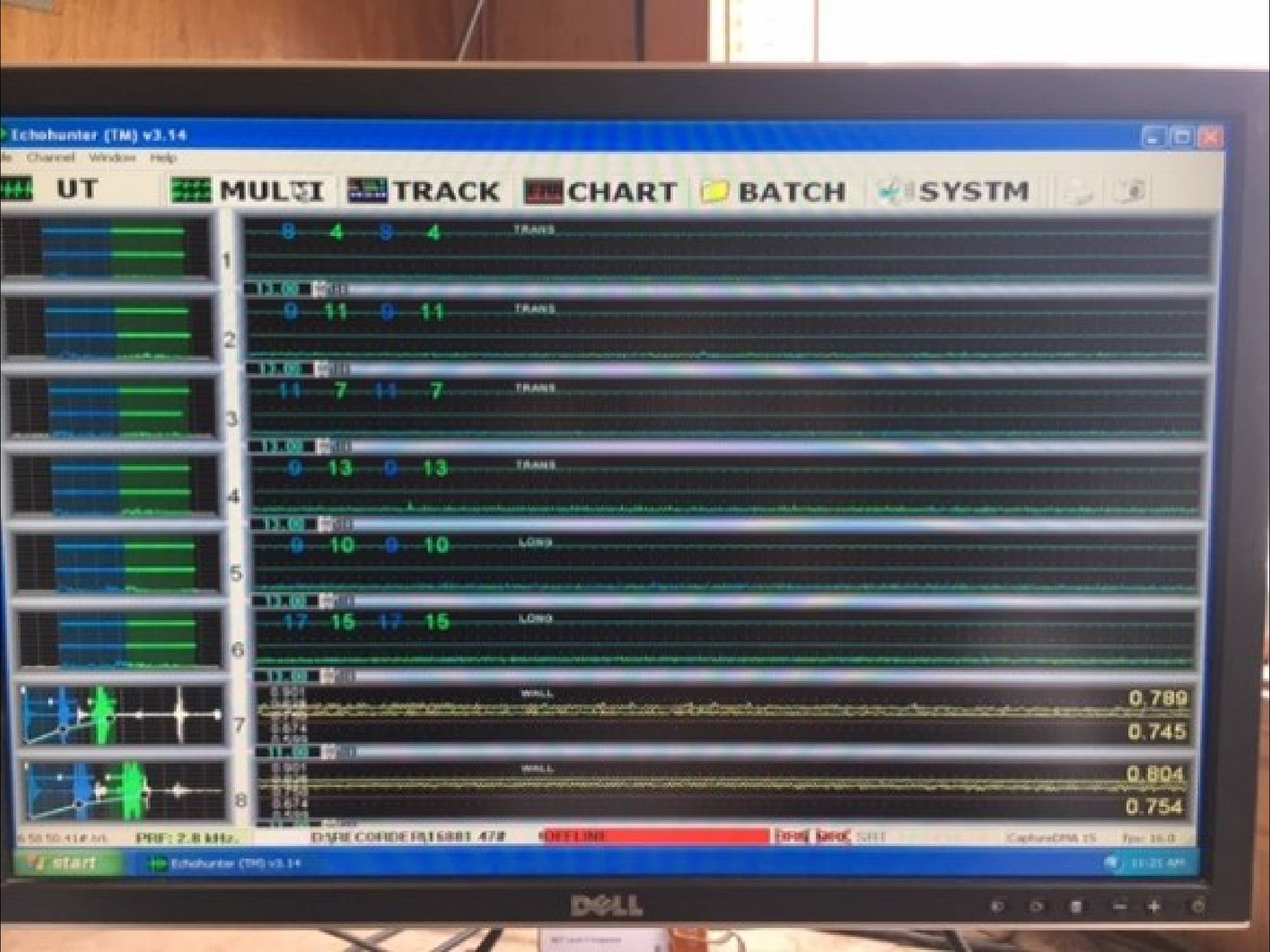

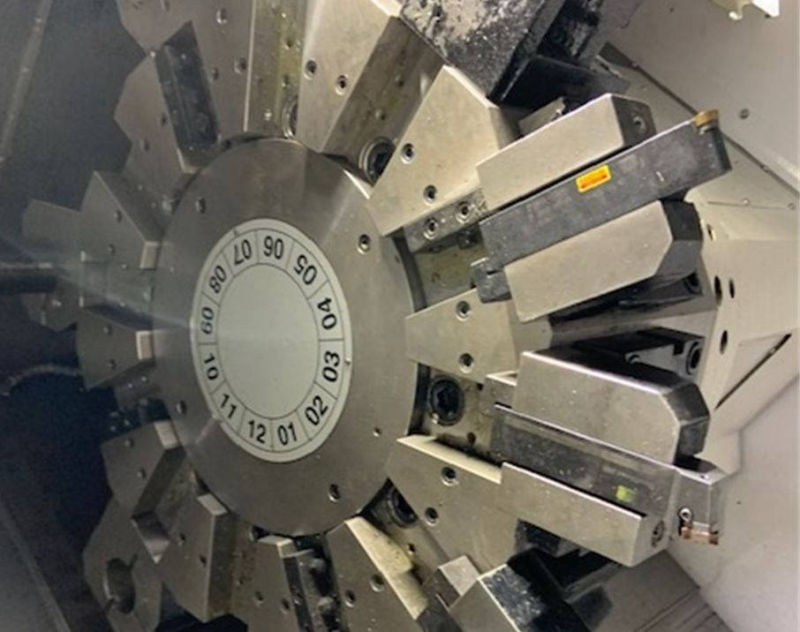

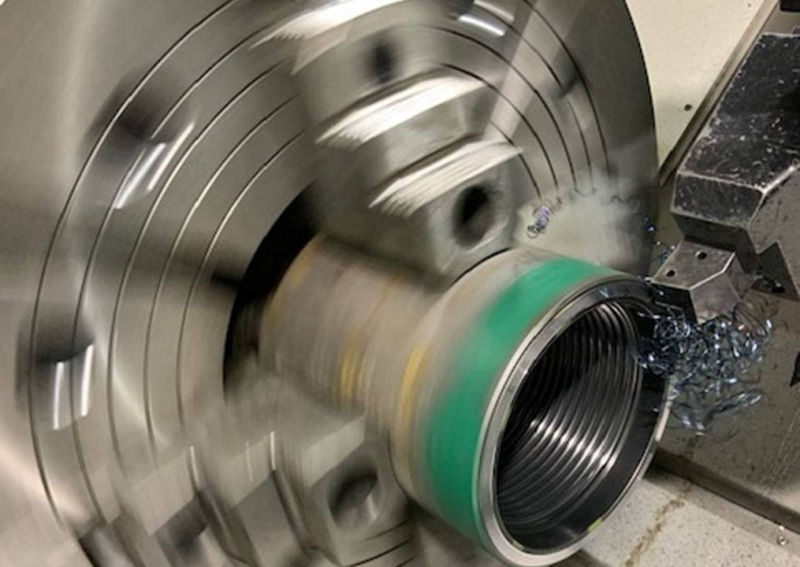

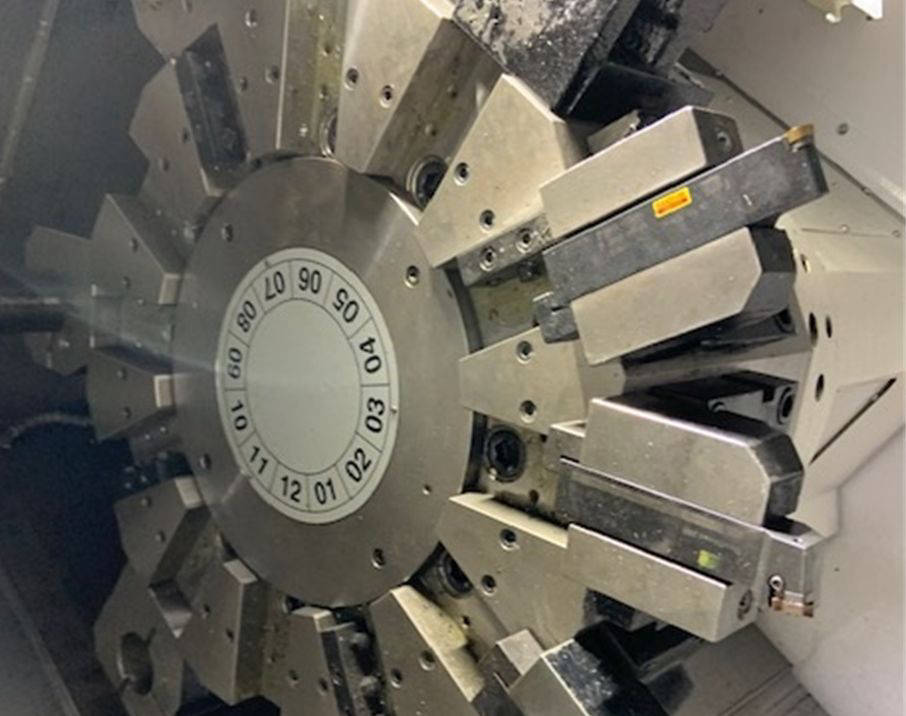

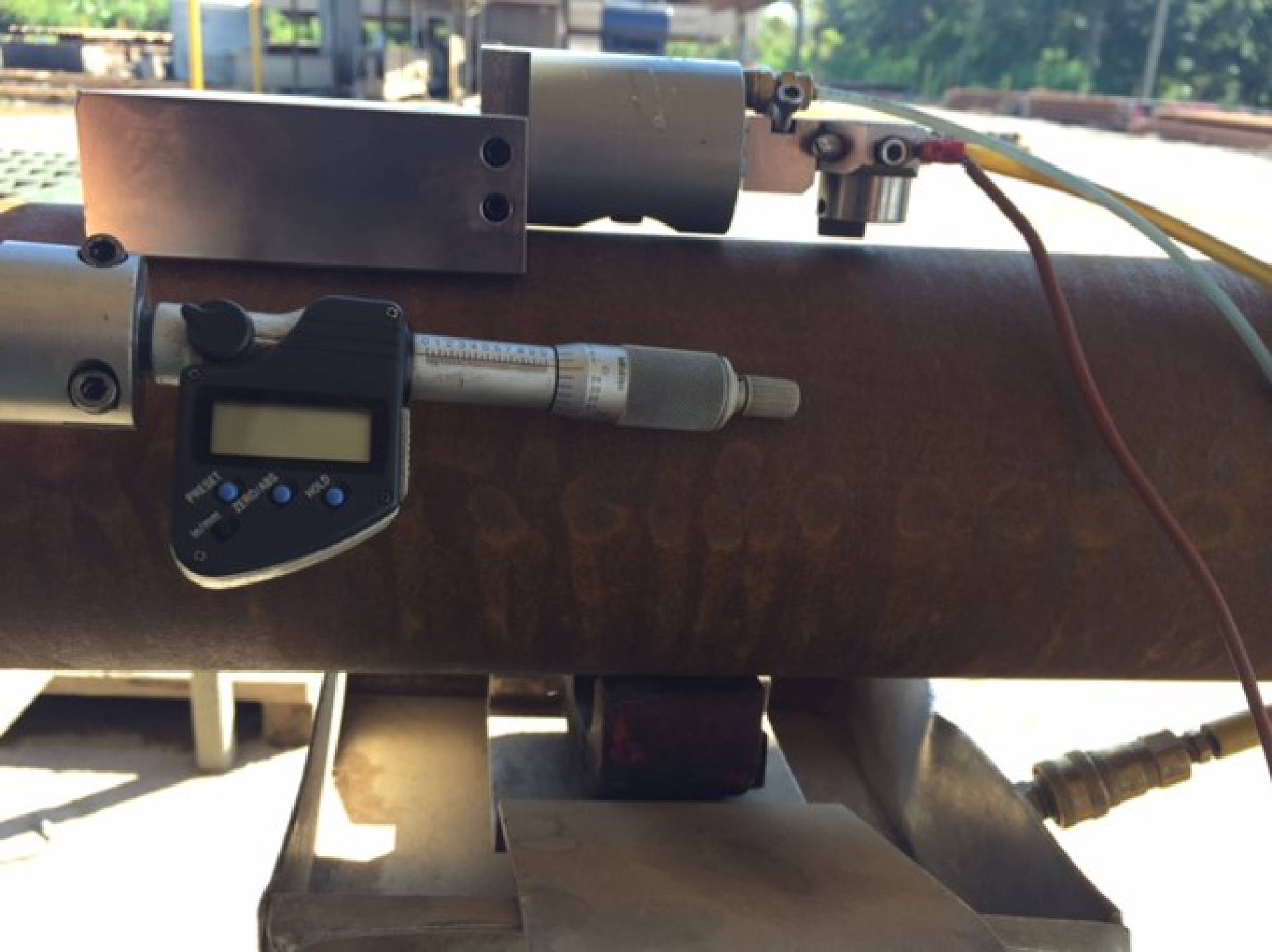

Fitzgerald Inspection, Inc. developed and designed a mechanical unit to handle nominal weight and thick wall Range II or III drill pipe. Compounded with a New Tech® systems “Head” and Magnetic Analysis Corporation (MAC System) based out of New York, FII has taken the best of all worlds to provide volumetric Flaw Detection of Transverse, Longitudinal and Full Length Wall Recordings.

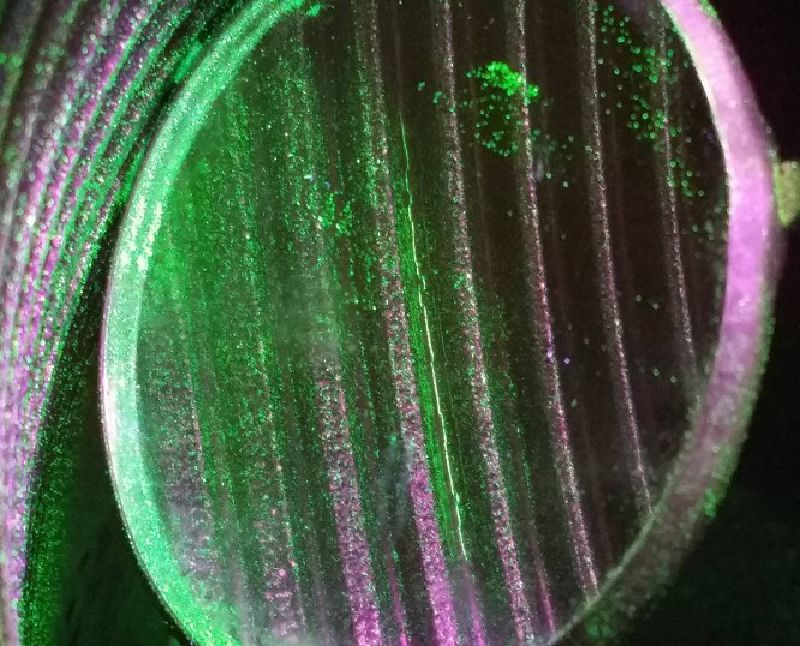

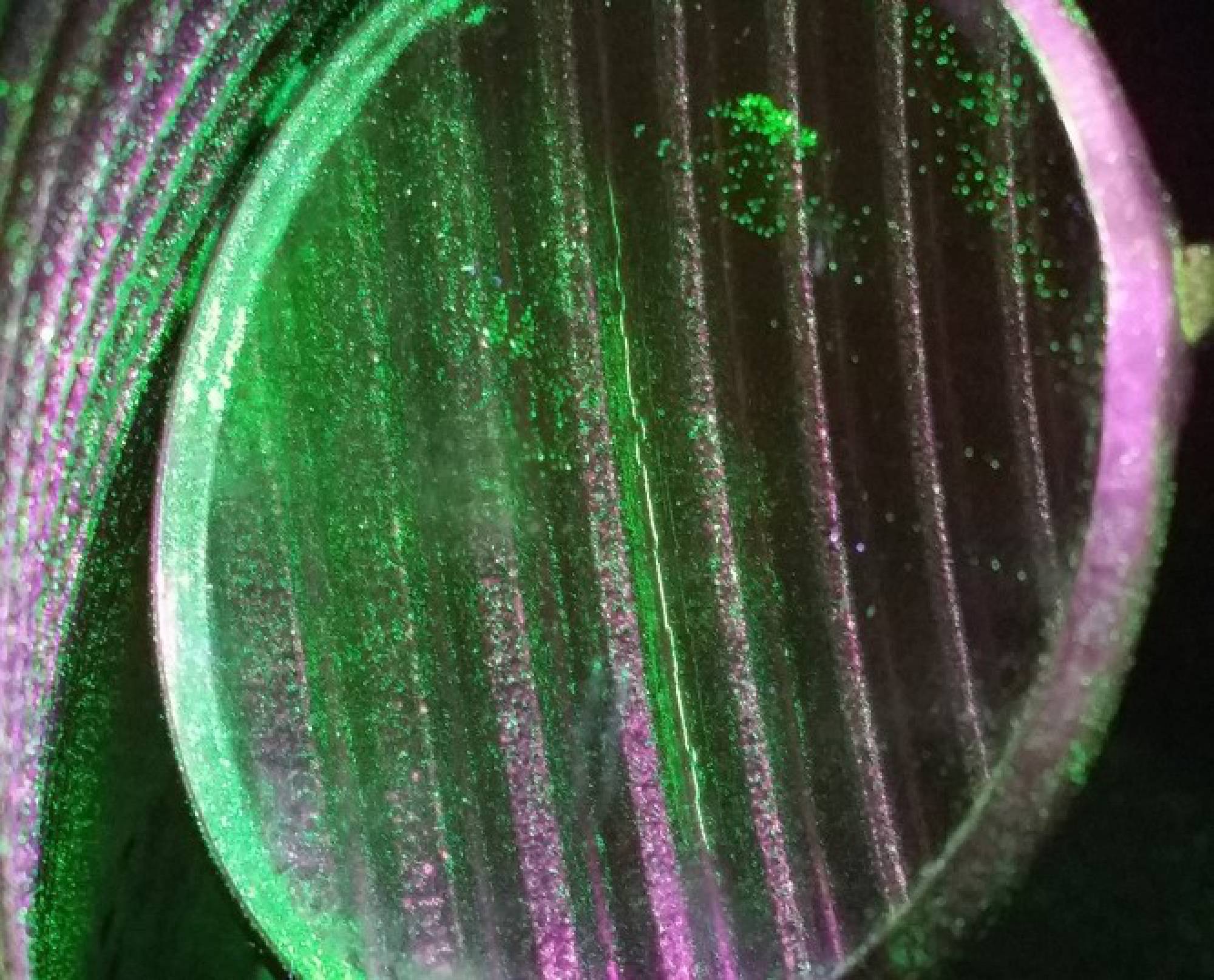

The “Head” is equipped with transducer holders that can be manipulated so the signal response is sharp, and at the peak angle compared to the EDM test notch.

FII uses 3.5 MHz x ½” Diameter spherically focused transducers

All beam profiles are verified and recorded in our calibration program.

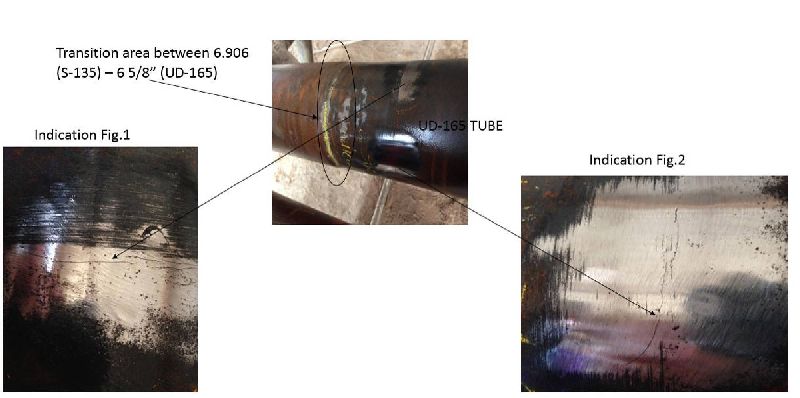

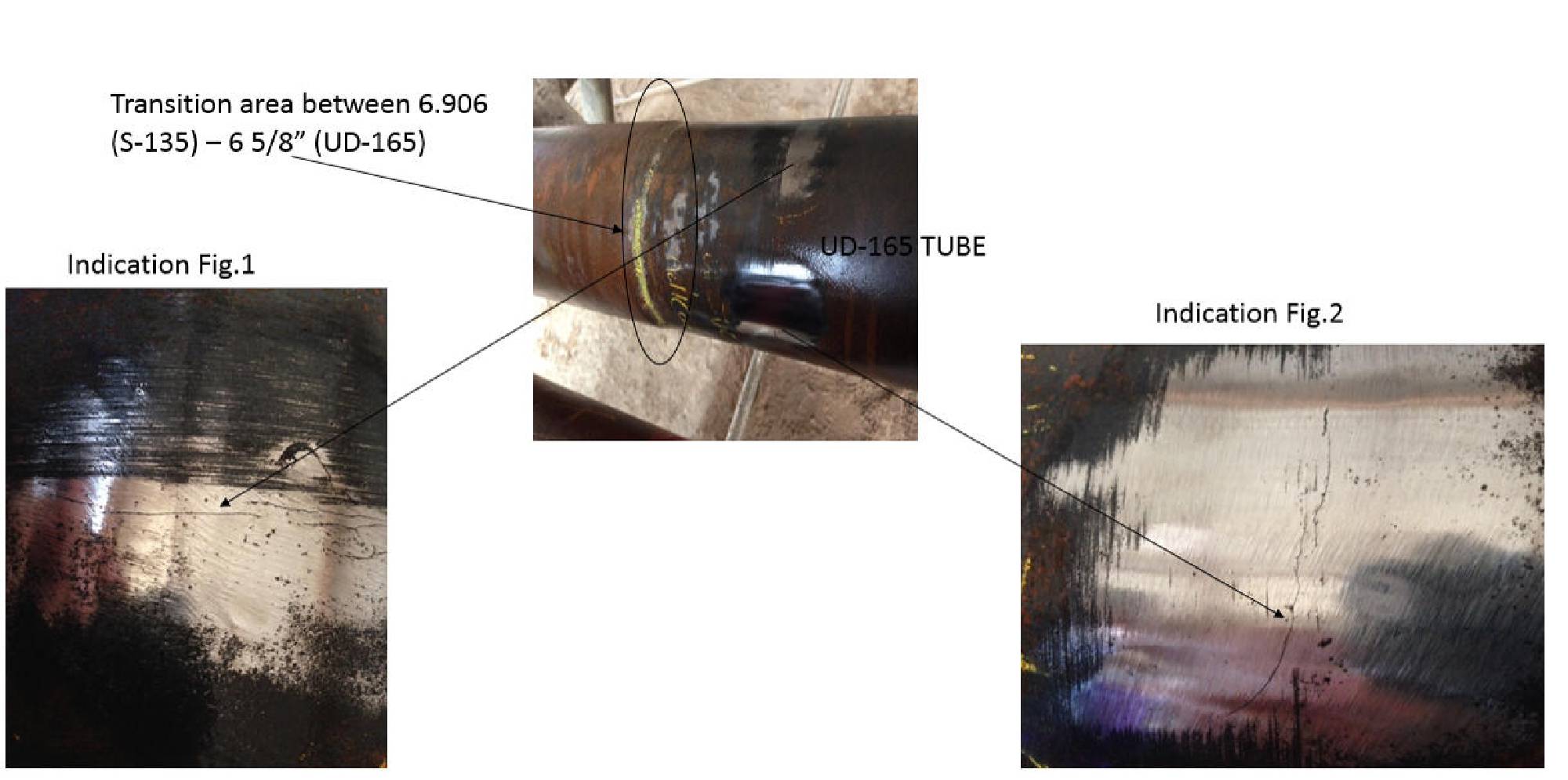

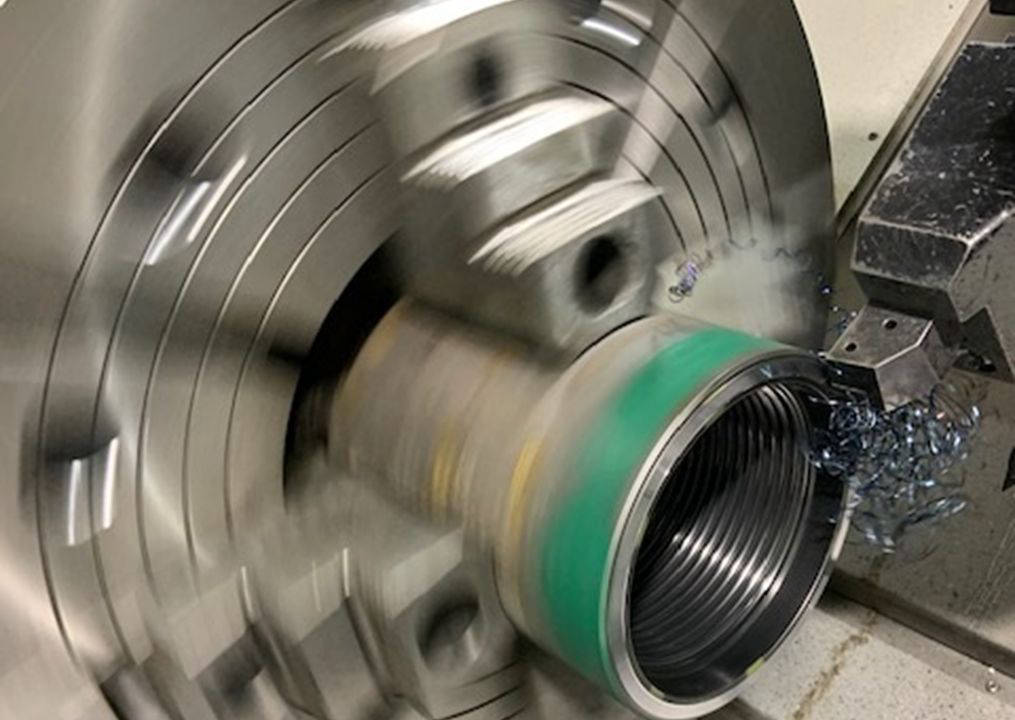

The 12” FLUT “Head” allows for close inspection onto the tool joint taper during scanning and can be used in lieu of a traditional hand scan wedge (which has many uncontrolled parameters) .

The “Head” is designed to be of the immersion type allowing for minimum interfaces and better sound/signal retrieval, unlike a traditional Lucite head on other machines.